About us

Our Story

Takumi Parts is a company dedicated to precision machining and mechanical manufacturing. We focus on creating components for the automotive sector of non-conventional vehicles and the industry in general. Takumi Parts was born in 2007 when Javier Suárez identified the need for technical solutions to address the mechanical components and spare parts shortage to restore and conserve historic vehicles. The same applies to the technical needs of Motorsport competition.

Over time, Mario Ruiz, an engineer with extensive experience in the design, development, and management of engineering projects, who had worked in several countries worldwide, joined the project. The merge of Javier’s experience of more than 25 years as a machinist, his encyclopaedic knowledge of classic and historic vehicles, as well as his craftsmanship skills in machining and mechanical manufacturing, together with Mario’s experience and knowledge in international markets, engineering and management, resulted in the birth of Takumi Parts S.L. in 2022.

This company aims to provide solutions to the manufacturing challenges of the automotive sector in particular and other industries in general, from precision machining to single-part manufacturing. The combination of both founders’ experience, knowledge and passion is the solid foundation on which Takumi Parts has become a benchmark in precision machining and mechanical manufacturing, providing customised technical solutions to meet its customers’ particular and most demanding needs.

Our Philosophy

The Fusion of Craftsmanship and Innovation

At Takumi Parts, our philosophy is based on the belief that true excellence is found in the fusion of traditional craftsmanship and technological innovation. We strive for perfection in every project, combining craftsmanship skills honed over the years with the latest precision machining tools and techniques. We value artisans’ legacy, dedication to quality, and meticulous attention to detail. For this reason, our order of priorities is always safety, quality, and production volume.

We are influenced by traditional Japanese philosophy in terms of the values of work and constant improvement, and we apply the concepts of Takumi and Kaizen to everything we do.

Takumi

Takumi means “craftsman” in Japanese, but this concept transcends its literal meaning in traditional Japanese philosophy. Takumi defines the pursuit of excellence. A way of thinking that drives you to work every day with discipline and perseverance to become a master.

Master Takumi dedicates his life to refining the technique and understanding the nuances of his craft in detail, using Kaizen to get as close as possible to perfection.

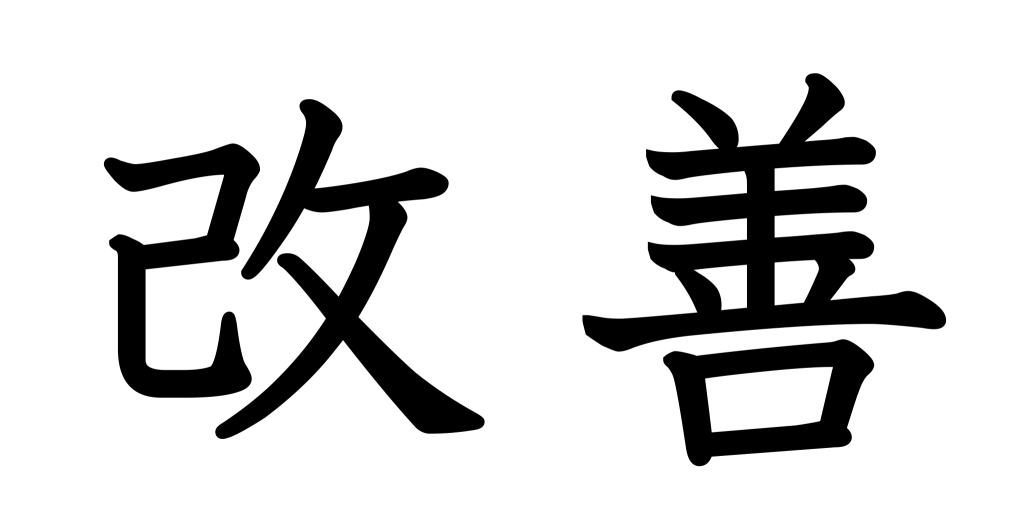

Kaizen

Kaizen is a Japanese concept that refers to continuous improvement. It is based on making incremental and constant improvements in all process aspects.

Kaizen involves a mindset of constant pursuit of excellence and innovation. The intention is to identify and eliminate waste, optimise efficiency, and encourage the participation of all organisational members.

Through the 5S system, this way of seeing and understanding work has been adapted to modern production and management needs.

5S Method

The 5S method is a Japanese management technique used to organise the workspace efficiently, improve productivity, and promote a safe and orderly work environment. The 5S represents five Japanese words: Seiri, Seiton, Seiso, Seiketsu, and Shitsuke.

The 5S method is robust for achieving an efficient, safe, and productive work environment. By implementing 5S systematically, organisations can improve employees’ quality, efficiency, and well-being, creating an environment conducive to operational excellence.

Need a solution? Contact us!

In 2022, Takumi Parts received the consideration of “Innovative Technology-Based Company” and the support of the Government of Cantabria (Spain) from the Ministry of Industry and Innovation through the Society for the Development of Cantabria (Sodercan) within the program that promotes the creation of new innovative companies with ambition and growth potential, knowledge, and skilled employment.

AID FILE NUMBER: P223-CE-094

Takumi Parts, S.L. has received a subsidy from the Society for the Regional Development of Cantabria (SODERCAN) for an amount of 18,487.93 euros for investment in capital goods, constitution and start-up during the period from its creation until August 2023, within the framework of the EMPRECAN plus 2023 programme.

Likewise, Takumi Parts, S.L. informs that it has obtained other aid or subsidies for executing this project and that they are compatible with other aid or subsidies.

The annual remuneration of the people who hold the administrative bodies

By the provisions of Law 1/2018, of 21 March, on Transparency of Public Activity, we inform you that the administrative and/or management bodies of the company Takumi Parts, S.L., such as the presidency, the general secretary, the management, the treasury, and the technical management, received annual remuneration and compensation totalling 21,000 euros in the 2023 financial year.

Services

Machining and Mechanical Manufacturing

– Single-Unit

– Short Series

– Precision Machining

– Prototypes and handling & control tooling

Engineering and design

– CAD/CAM

– Reverse Engineering

– Development and Design

– SLA Additive Manufacturing

Technical Consulting

– Machining Training

– Production Method Consulting

– Classic Vehicle Purchase & Sale Advice

– Desired Vehicles Finder

Work Areas

Historic vehicle

Competition vehicle

Industry

Takumi Parts

About Us

Contact